Markets

At Swiss-Tech we manufacture Swiss precision machined parts for critical applications in the aerospace, medical, and other high-end industrial markets.

Medical

Our ISO 13485 certification allows us to build a wide variety of medical components. We have been expediting as many as 20 parts being used to treat COVID-positive patients, including medical instruments, ventilators, respirators, and blood testing equipment. Our team has also been working on a part that is being used for the development of an antibody vaccine.

When we started producing and expediting these essential parts, we shared the information with our workforce. The information was very motivational to our team to continue to produce and expedite the parts and to stay healthy.

Our team at Swiss-Tech has been making continuous improvements over the last several years to be able to fulfill new and expedited requests. The pandemic is not something anyone could have expected or wanted to go through, but we are proud of how our team has been able to step up and help our clients who are providing important health care products.

Aerospace

Aerospace applications necessitate high-performance parts with complicated validation requirements and exacting quality controls. The Swiss-Tech team’s focus on process controls, quality at the source, and utilizing the 2-bin method guarantees part repeatability to meet customer expectations in the aerospace industry.

Aerospace parts tend to have complicated geometries, features or dimensional characteristics, and are often made from specialty alloys or composites. Inconel is one example of a specialty material often selected because of its resistance to oxidation and high tensile strength at temperature. These characteristics also make it incredibly challenging to machine.

If the raw material is available in bar stock Swiss-Tech can develop a process to make parts. We support our customers by applying our engineering experience to provide parts with exceptional performance, strength, and extreme temperature resistance.

At Swiss-Tech, we are AS9100 certified and have the team, systems, and process controls to meet those standards.

Our engineering team understands what it takes to develops accurate processes on difficult parts quickly. We work hand in hand with our customer to define key dimensional characteristics and monitor using a multiple axis approach. We consistently hold tolerances to 0.0001” (+/-0.00005”).

Space

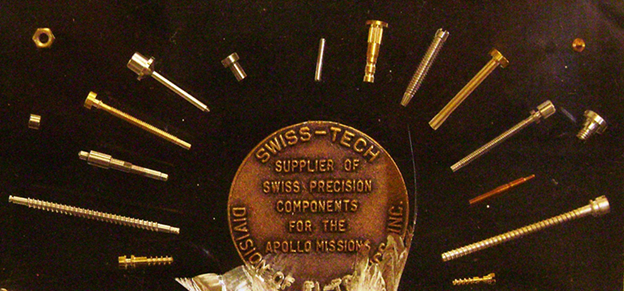

Our Contribution to the First Moon Landing

Swiss-Tech is proud to have contributed to the lunar landing with our high-quality, precision machining services. At Swiss-Tech, we still find it inspiring that our reputation for quality aerospace machining had already taken root just four years into our company’s founding in 1965. NASA contracted 18 precision components from us for the Apollo 11 mission.

The precision machine components we produce are expertly crafted for mission critical applications, and the lunar landing was no exception. Our reliable and robust components contributed to the composition of both the astronauts’ life-support systems and the spacecraft’s instrument panels.